Electrical Risk Assessment

Electrical hazards continue to threaten safety of people and property in the form of shocks, burns, injury, fire and explosion. As electricity has become an indispensable part of our life, electrical risks are to be managed effectively.

Any disruption in the electrical system can bring the complete industry to a stand-still, thus making it a highly critical part of any installation.

- In process industries, fires arising from electrical faults are highly probable, especially in industries that handle flammable chemicals.

- In service industries such as information technology, telecommunications, business interruption losses due to electrical hazards (fire in server room, fire in cable gallery, damage of expensive communication equipment, loss of data, etc.) could be substantial.

Methodology:

- Pre Site Visit data

- Opening meeting

- Pre Audit questionnaire

- Physical Inspection

- Discussion

- Document review (Standards and Emergency Response Plan)

- Closing meeting

- Report and observation submission.

- Establish clear communication channels for reporting electrical hazards, incidents, and suggestions for improvement.

- Generate reports summarizing the assessment results, risk levels, and recommended actions.

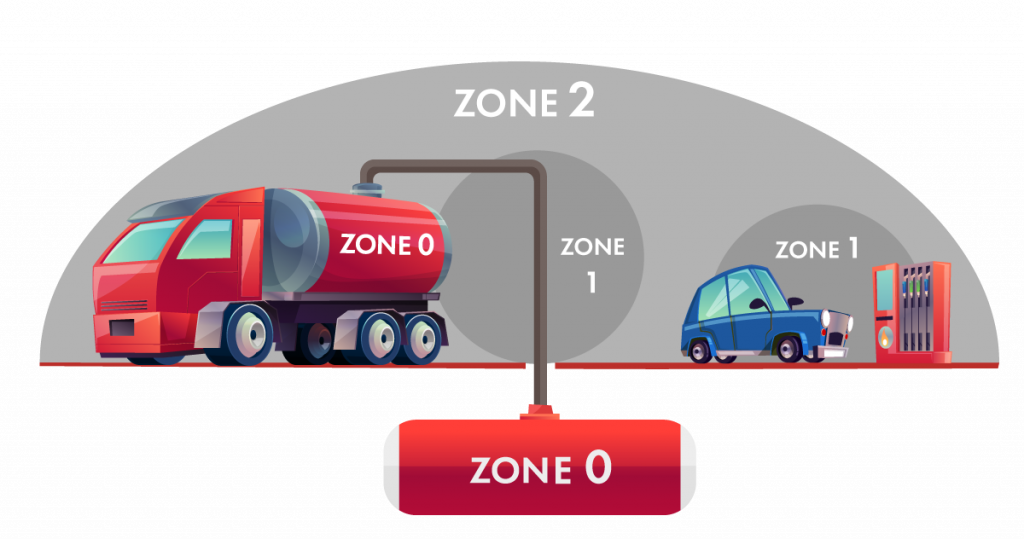

Hazard Area Classification

The purpose of hazard area classification is to assess the risk of an explosion and determine the appropriate measures to ensure electrical safety in those areas. The classification is typically based on the likelihood and extent of the presence of hazardous materials.

Review of likelihood of occurrence of explosive atmospheres and their persistence.

Classification of zones as explosive, less explosive etc. based on IEC – 60079-10 standard.

Zone 0: This zone represents areas where a hazardous atmosphere is present continuously or for long periods.

Zone 1: In this zone, a hazardous atmosphere is likely to occur during normal operations, but not continuously or for long durations.

Zone 2: This zone is characterized by the occasional presence of a hazardous atmosphere due to abnormal conditions or malfunctions.

Static Charge Survey

Static electricity possesses the potential to ignite and lead to fires and explosions in environments where flammable atmospheres, like solvent vapors or dust clouds, may be present.

To mitigate these risks, we conduct thorough surveys to identify the presence of static charge and implement comprehensive prevention and control measures.

Lightning Protection Survey

This review focuses on evaluating the Lightning Protection System specification and current lightning protection measures.

It examines their adherence to standards like IS 2309, NFPA 780, and OISD 180 to ensure the system's efficacy and compliance in mitigating the hazards associated with lightning strikes.

Thermography Monitoring

Thermography is used to see the excess heat (resistance) so that problems can be found and maintenance personnel can act to correct the problem before the component fails, that can lead to cause damage to the component, safety hazards and/or production downtime.

Following are the steps to Thermography Monitoring

- To carry out ‘hot spot analysis’ of electrical system.

- Conditional monitoring of all electrical equipment.

- To furnish detailed report on findings of these reviews with photograph’s.

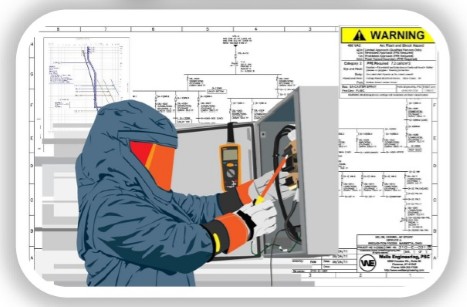

Arc Flash Analysis

An arc flash occurs when an electrical path is broken in some way and the electricity jumps or “arcs” to a nearby grounded object.

Arc Flash analysis is a study of a facilities electrical system. This Study will determine potential weak spots throughout the electrical system, spots that would pose the danger of electrocution, electrical incidents, and even electrical arc blasts.

We refer to the NFPA 70E Standard & Guidelines.

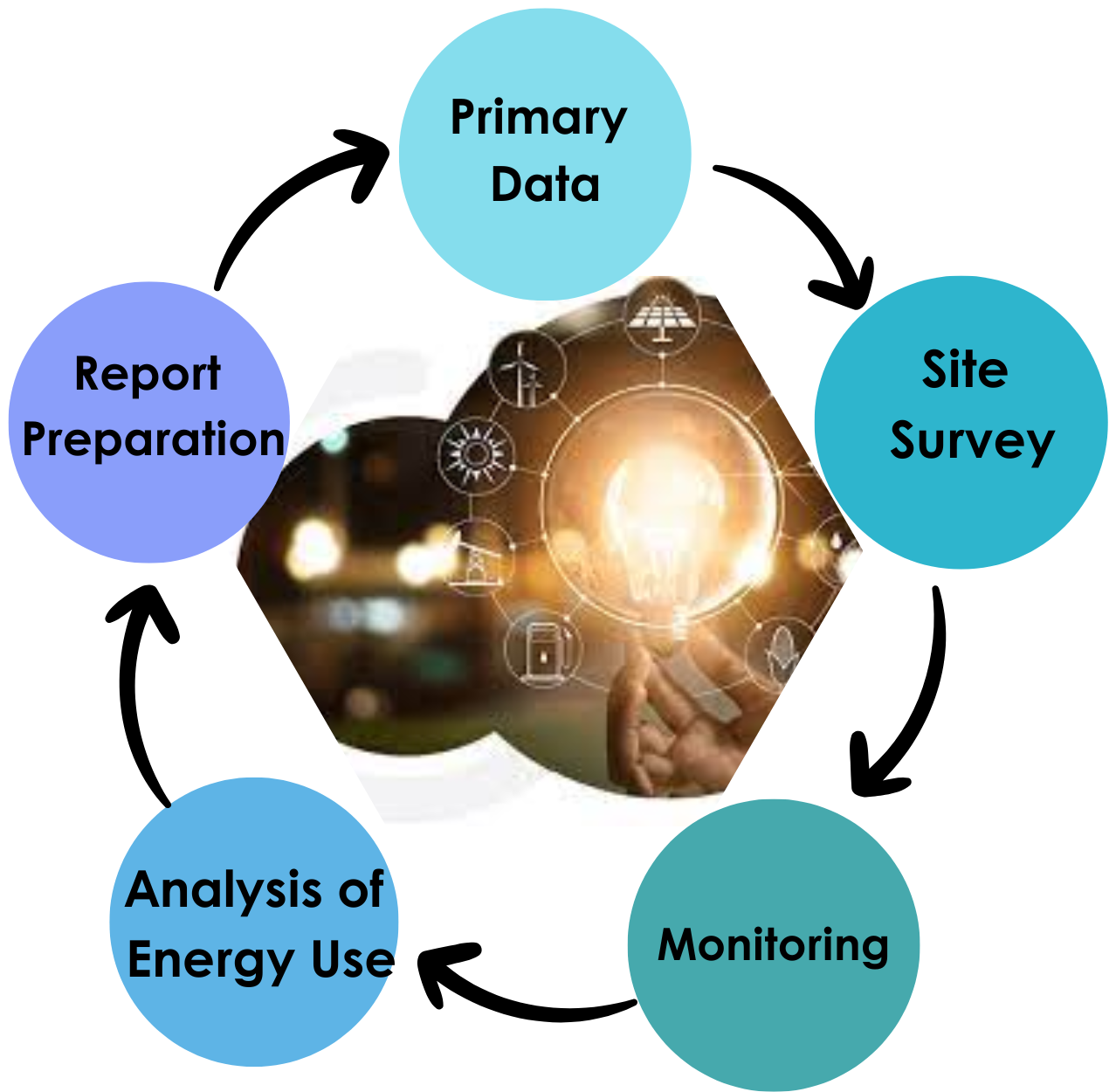

Energy Audit

An energy audit is a comprehensive assessment of energy usage and efficiency in a building, facility, or system. It involves the evaluation and analysis of energy consumption patterns, equipment performance, and operational practices to identify areas where energy is being wasted or could be used more efficiently.

Our energy audit service is designed to help businesses and individuals optimize their energy consumption and reduce costs. We offer comprehensive energy audits that assess your energy usage patterns and identify areas for improvement.

Moreover, our energy audit service, you can uncover energy-saving opportunities and implement strategies to reduce your carbon footprint. The purpose of an energy audit is to identify opportunities for energy savings, reduce energy costs, and improve overall energy performance.

Other Electrical Services provided by Green Circle Inc are:

- Electrical Safety Audit

- Electrical Installation Risk Assessment

- Electrical Maintenance Audit and Manual

- Earthing and bonding Study

- Harmonic Study

- Panel Risk Assessment

Following is partial Client list for Risk for Electrical Services:

| Sr. No. | Name of the Client | Sector | Type of Project/Assignment |

| 1 | Aarti Industries Ltd. | API / Bulk Drug | Electrical Safety Audit |

| 2 | Akzo Nobel Coatings India Private Ltd. | Coating | Hazardous Area Classification |

| 3 | Ambuja Cements Ltd. | Cement | Legal Compliance Audit, Electrical Safety Audit, Lightening Protection, Hazardous Area Classification |

| 4 | Asian Paints Ltd. | Paints | Illumination Survey, Hazardous Area Classification |

| 5 | Banco Products Pvt. Ltd. | Auto Ancillary | Electrical Safety Audit |

| 6 | Bharat Alluminium Co. LTD. (BALCO) | Aluminium | Lightening Protection System |

| 7 | Cadila Pharmaceuticals Ltd. | Pharmaceuticals | Safety Audit, Fire Risk Assessment |

| 8 | Fosroc Chemicals Ltd. | Specialty Chemical | Electrical Safety Audit, Hazardous Area Classification |

| 9 | Gail (India) Limited (GAIL) | Gas Distribution and Petrochemicals | Static Charge Survey |

| 10 | Henkel Chembond Surface Technologies Ltd. | specialty chemicals | Hazardous Area Classification, |

| 11 | Heranba Industries Ltd. | Agrochemical, Pigment | Static Charge Survey, |

| 12 | Kemrock Industries & Exports Ltd. | Fiber & Polymer | Static Charge Survey |

| 13 | Reliance Industries Ltd. | Refineries | Thermography, Fire Risk Assessment |

| 14 | Reliance Compressor Stn No.08 & 10 | Gas Distribution | Fire Risk Assessment, Safety Audit, Lightening Protection, Solar Cooking Systems, Thermography |

| 15 | Select Infrastructure Pvt. Ltd. | Infrastructure | Fire & Safety Audit, Energy Audit |

| 16 | TajSATS Air Catering Ltd. | Hotel | Electrical Safety Audit |

| 17 | The Phenoix Mills Ltd. | Mall | Comprehensive Environment, Health & Hygiene, Safety & Security Audit |